Punched aluminium parts are ideal for customers requiring very close tolerances and low cost. Perfect for higher volumes, we offer punched aluminium parts from 6 in-house presses of various power ratings up to 40 tonnes.

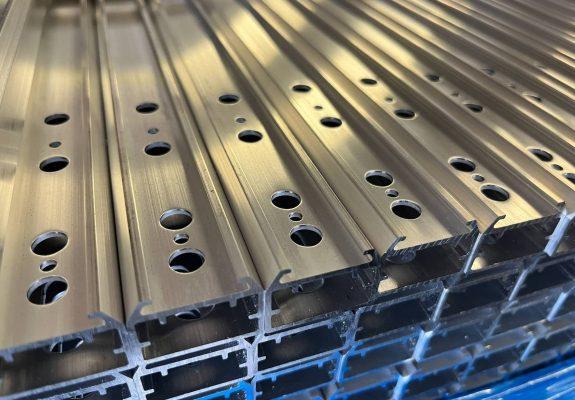

Utilising customer specific dies, our punching service is a quick and efficient way of repeating holes and patterns in a profile. Any number or slots, holes of any shape, embossing, debossing and manipulation can be achieved with one stroke of a press. For higher volume products this process offers the benefits of lower cost and closer tolerances.

With tolerances from ± 0.10mm, we use aluminium punching to fulfil orders for profiles used in applications such as furniture systems, wall cladding profiles, shelf support rails and parts for the lighting industry.

Aluminium punching requires investment in a punch tooling however initial costs are outweighed by the lower part cost affording by this efficient fabrication method. Our sales team are on hand to offer advice on this or any other aluminium fabrication requirements you may have. Please contact us for costs, advice and 3D printed samples of your application.